CPU Fan in Motherboard Design, CPU Front Panel Integration & PCB Manufacturing Standards

Understanding CPU Fan in Motherboard Systems

A CPU fan in motherboard design plays a critical role in thermal management & system stability. The motherboard integrates dedicated fan headers that regulate voltage, PWM control & speed monitoring. Manufacturers design the CPU motherboard fan circuit to ensure consistent airflow while preventing overheating under continuous load. Proper PCB layout supports signal integrity & reduces electrical interference within high-frequency processing environments.

CPU Motherboard Fan Header & Electrical Design

The CPU motherboard fan header typically includes 3-pin or 4-pin connectors. A 4-pin PWM interface enables dynamic speed adjustment based on processor temperature. PCB engineers route power & control traces carefully to prevent voltage fluctuation & signal noise. Stable copper thickness, accurate impedance control & optimized grounding improve reliability in high-performance computing systems.

CPU Front Panel Interface & System Connectivity

The CPU front panel connector on a motherboard handles power switch, reset switch, HDD LED & system indicator signals. Although it appears simple, this interface requires accurate pin mapping & trace planning during PCB manufacturing. Poor routing may cause unstable boot signals or inconsistent system response. Professional PCB manufacturers ensure clean layout segmentation between power, control & high-speed data lines.

Key Design Factors for CPU Fan & Front Panel Integration

When designing motherboard PCB solutions, manufacturers focus on:

-

Accurate PWM fan control circuit for stable speed regulation

-

Optimized copper thickness to support consistent voltage supply

-

EMI shielding & grounding design to reduce interference

-

Proper header placement to ensure easy system assembly

-

Thermal-aware PCB layout that supports airflow efficiency

These design strategies improve long-term motherboard performance & reduce system failure rates.

Technical Overview of CPU Fan & Motherboard Interfaces

| Component | Function | Engineering Requirement | Manufacturing Impact |

|---|---|---|---|

| CPU Fan Header | Supplies power & PWM signal | Stable voltage & noise control | Prevents overheating & instability |

| PWM Control Circuit | Adjusts fan speed | Clean signal routing | Enhances thermal efficiency |

| Front Panel Header | Connects system switches & LEDs | Accurate pin layout | Ensures stable boot & operation |

| Ground Plane | Reduces EMI | Controlled impedance | Improves reliability |

| PCB Material | Supports heat dissipation | High Tg material selection | Extends board lifespan |

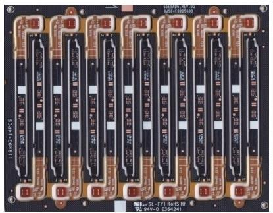

PCB Manufacturing Standards for Motherboard Applications

A professional PCB manufacturer such as RJX Multilayer PCB focuses on precision drilling, controlled impedance routing & multi-layer board fabrication. High-density interconnect technology supports CPU fan motherboard circuits & front panel connectors without compromising electrical performance. Strict quality inspection ensures solder mask accuracy, via reliability & trace integrity.

Manufacturers apply automated optical inspection (AOI), electrical testing & thermal reliability checks before shipment. This process guarantees stable performance in gaming systems, industrial computing & embedded devices.

Why Choose a Professional PCB Manufacturer

For OEM motherboard projects, choosing an experienced PCB manufacturer ensures:

-

Multi-layer PCB capability for complex CPU & fan circuits

-

High-frequency material support for stable processor environments

-

Strict quality control & global compliance standards

-

Fast prototyping & scalable mass production

Reliable motherboard performance starts with high-precision PCB manufacturing.

FAQ: CPU Fan in Motherboard & PCB Design

Q1: What is the difference between 3-pin & 4-pin CPU fan connectors?

A 3-pin connector provides voltage-based speed control, while a 4-pin connector supports PWM control for more precise thermal management.

Q2: Why is PCB layout important for CPU fan circuits?

Proper routing reduces voltage drops, minimizes interference & ensures stable cooling performance.

Q3: Does front panel design affect motherboard stability?

Yes. Incorrect pin routing may cause boot errors or unstable system response.

Q4: What PCB materials are best for motherboard applications?

High Tg FR-4 materials or advanced thermal substrates improve durability under sustained processor load.

Q5: How does manufacturing precision affect CPU fan performance?

Accurate copper thickness, clean signal routing & reliable solder joints directly impact voltage stability & long-term performance.