Why Choosing the Right PCB Manufacturer Matters for Your Electronics Project

Discover why choosing the right PCB manufacturer is crucial for your electronic project. Learn how quality, certifications, production capabilities, and delivery performance directly impact reliability and success.

Why Choosing the Right PCB Manufacturer Matters for Your Electronics Project

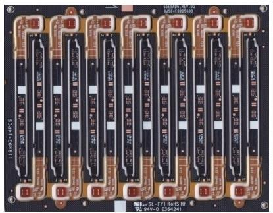

In the world of modern electronics, the Printed Circuit Board (PCB) is the foundation upon which every device is built. From simple household appliances to high-performance industrial equipment, PCBs form the backbone of all electronic systems. However, not all PCBs are created equal — and the success of your project depends heavily on choosing the right PCB manufacturer.

The Role of PCB in Modern Electronics

A PCB connects and supports all electronic components through conductive pathways, signal traces, and pads. It determines not only how efficiently current flows but also how durable and reliable the entire product will be. As devices become smaller, faster, and more complex, the quality of the PCB becomes even more critical.

Today’s manufacturers offer different types of PCBs — single-sided, double-sided, and multi-layer — as well as advanced technologies like rigid-flex and high-frequency boards. Each type requires specific design considerations, materials, and manufacturing expertise. Choosing a capable PCB supplier ensures that every technical requirement is met with precision.

Understanding the PCB Manufacturing Process

PCB manufacturing is a complex, multi-stage process involving design validation, material selection, etching, drilling, plating, solder mask application, surface finishing, and final testing. Any small deviation at one stage can affect performance and yield.

A professional PCB manufacturer uses advanced equipment and strict quality control to maintain consistency. For example:

-

Material Selection: High-quality laminates like FR-4, Rogers, or metal-core substrates ensure better thermal and electrical performance.

-

Surface Finish: Options such as HASL, ENIG, or immersion silver impact solderability and longevity.

-

Testing: Automated Optical Inspection (AOI) and Electrical Testing guarantee defect-free products before shipment.

Partnering with an experienced manufacturer means you can rely on stable processes, accurate tolerances, and consistent quality — which are vital for high-reliability applications like automotive, aerospace, and medical electronics.

Quality Assurance and Certification

One of the strongest indicators of a reliable PCB manufacturer is its certification and quality management system. Leading manufacturers operate under ISO9001, IATF16949, or UL certification, ensuring every step of the production process meets global standards.

Moreover, professional suppliers conduct rigorous inspections for impedance control, solderability, and environmental compliance (RoHS and REACH). These practices reduce the risk of product failure and increase your confidence in long-term performance.

Supply Chain and Delivery Capabilities

Beyond technical expertise, a good PCB partner must also deliver efficiency. Timely delivery, transparent communication, and flexibility in production scheduling can make a huge difference for your business.

Manufacturers with in-house capabilities — from prototype fabrication to mass production — provide better lead time control and cost management. They can also help optimize your design for manufacturability (DFM), reducing errors and improving yield.

In global projects, having a supplier with both domestic factories and international offices can be a major advantage. It ensures localized service, faster response times, and easier logistics coordination.

What to Look for When Selecting a PCB Manufacturer

When evaluating potential suppliers, keep the following factors in mind:

-

Experience and Expertise – How long have they been in the PCB industry? Do they have experience with your specific application, such as high-frequency or high-layer-count boards?

-

Manufacturing Capabilities – Can they produce the board size, layer count, and materials you require? What are their minimum trace widths and spacing tolerances?

-

Quality Systems – Are they certified and do they provide detailed inspection reports?

-

Communication and Service – How responsive and transparent are they during the quotation and production stages?

-

Scalability – Can they support both small prototype orders and large-scale production runs?

Choosing a partner that meets these criteria will reduce risks, ensure design compatibility, and ultimately shorten your time to market.

The Cost vs. Quality Balance

While cost is always a key consideration, the cheapest option is not always the best. Low-cost suppliers may cut corners on material quality or testing procedures, leading to hidden reliability issues. On the other hand, a slightly higher investment in a qualified manufacturer can result in better yield, fewer returns, and longer product lifespan — which saves money in the long run.

The goal should be to strike the right balance between cost, performance, and reliability. A trustworthy PCB manufacturer will work closely with you to achieve that balance by offering engineering support, process optimization, and transparent pricing.

Conclusion

The printed circuit board is the heart of every electronic product — and choosing the right manufacturer determines how that heart performs over time. A professional PCB partner brings not only technical capability but also process stability, quality assurance, and dependable support.

Whether you’re developing prototypes for a startup project or scaling up for mass production, selecting a reliable PCB manufacturer is one of the most strategic decisions you can make. It ensures your designs come to life with precision, performance, and durability — helping your business stay competitive in the fast-moving electronics market.